With the progress of science and technology and the continuous upgrading of consumer demand, touch screen has been widely used in smart phones, tablet PCs, smart homes, automobiles, medical equipment and other fields. Different industries and different application scenarios have different needs for touch screens, which has led to the inevitable trend of touch screen customisation. For example, in the medical field, the touch screen needs to have high sensitivity, easy to clean, antibacterial and other characteristics; and in the field of industrial control, the touch screen needs to have high stability, wear-resistant, waterproof and dustproof characteristics.

The continuous innovation and upgrading of touch screen technology also provides strong support for customisation. In recent years, touch screen technology continues to develop in the direction of high precision, high sensitivity, power consumption, anti-interference and so on. At the same time, the continuous emergence of new touch materials, touch algorithms, touch chips and other technologies also provide more possibilities for the customisation of the touch screen. These technological innovations make the touch screen can better adapt to the use of different scenarios, to meet the user's personalised requirements.

In the future, touch screen customisation will show the following development trends:

1. technological integration and innovation: touch screen technology will be deeply integrated with other technologies such as artificial intelligence, Internet of Things, etc., to promote the development of intelligent and networked customised products.

2. market demand segmentation: with the continuous segmentation of the market and the diversification of consumer demand, touch screen customisation will pay more attention to the details and personalised needs to meet the differentiated needs of different users.

3. Collaboration and optimisation of the industrial chain: the cooperation between upstream and downstream enterprises in the industrial chain will be closer, forming a good situation of synergistic development and promoting the rapid response and efficient production of customised products.

The parts of the touch screen that can be customised are quite diverse to meet the specific needs of different industries and different application scenarios. The following are the customisable parts and their related descriptions:

1. Cover lens part:

- Material: Common cover materials include glass (e.g. tempered glass), PET (polyethylene terephthalate) film, and so on. Among them, the glass cover plate is popular because of its high hardness, scratch resistance and high light transmittance.

- Thickness: The thickness of the cover plate can be customised to suit the thickness requirements and weight limitations of different touchscreens. For example, the thickness of cover glass for industrial touchscreens may vary depending on the size of the LCD screen, commonly 0.55mm, 0.7mm, 0.8mm, 1.4mm, 1.8mm, and so on.

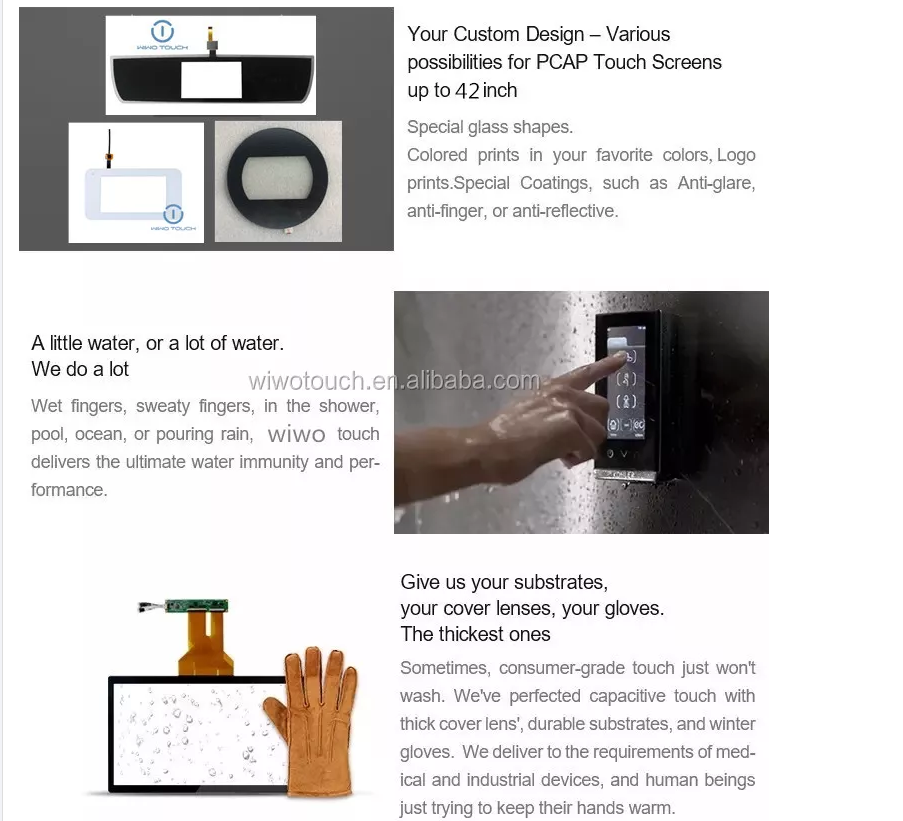

- Surface treatment: The surface of the cover can be specially treated, such as coating (e.g. AF anti-fingerprint coating), anti-glare, anti-fingerprint, anti-oil, anti-bacterial, etc., to enhance the user experience and the durability of the touch screen.

- Shape: The shape of the touch screen can be customised according to the design requirements of specific products, such as round, square, shaped, etc.

2. ITO sensor:

- Size: The size of the touch function chip can be customised according to the overall size of the touch screen to ensure an accurate fit.

- Type: The function sheet can be resistive, capacitive or other types of touch screen sensors, depending on the application requirements.

- Transmittance: A high transmittance function chip can ensure a clearer and brighter image display.

3. Chip:

- Model: The touch chip can be selected according to the performance requirements of the touch screen, and different models have different processing power, power consumption and cost.

- Function: Customised chips can achieve specific functions, such as multi-touch, gesture recognition, pressure sensing and so on.

4. PIN Definition: The PIN definition (pin definition) of the touch screen can be customised according to the interface requirements to ensure compatibility and stability with other electronic devices.

5. Thickness: In addition to the thickness of the cover plate, the overall thickness of the touch screen can also be adjusted according to the need to adapt to different installation space and aesthetic requirements.

6. Function buttons: virtual or physical buttons can be integrated on the touch screen, and the layout, size and shape of the buttons can be customised according to user habits and application scenarios.

7. FPC length: FPC (Flexible Printed Circuit) is an important connecting part between the touch screen and the main control board, and its length can be customised according to the distance between the touch screen and the main control board.

To sum up, the customisation of the touch screen is very extensive, covering almost all components of the touch screen. Through customisation, it is possible to produce touch screen products that meet the needs of specific applications, with high performance and good user experience.