R&D PROCESS

In the manufacturing process, from the production of touch sensor to the assembly and manufacturing of touch screens, every production process is closely related to the research and development technology. The R&D achievements of WIWOTOUCH's R&D team always injects fresh blood into the production and manufacturing process, improves the production process, and increases the production efficiency.

Laser etching process of ITO glass & ITO film

The chemical reaction between a specific Liquor and the ITO layer can remove the parts that are not covered by photoresistance, thus achieving the purpose of etching.

The mini line width/ trace spacing of ITO pattern is 35μm.

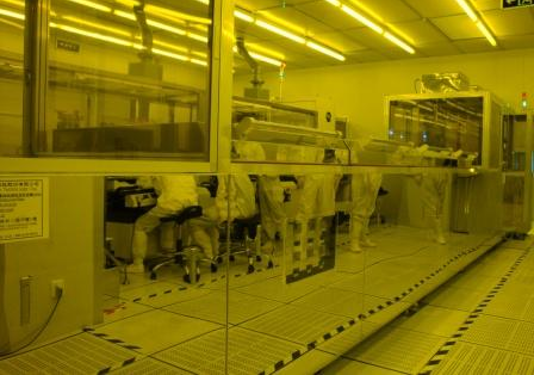

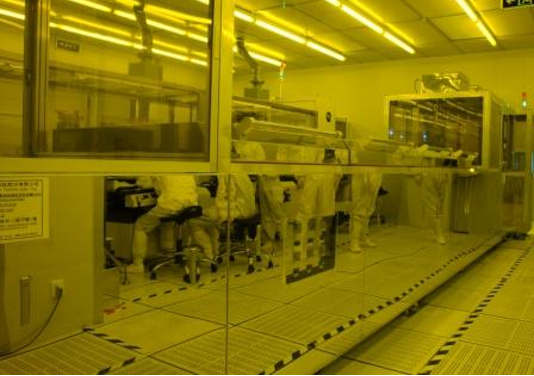

Automatic & semi-automatic process of

CTP assembly / CTP bonding with LCD

The automatic production line can increase the production efficiency by more than 50%, and the yield of bonding process is up to 99%.

The semi-automatic production line can be flexibly adjusted to fit the different product size, the operation space is relatively unrestricted.

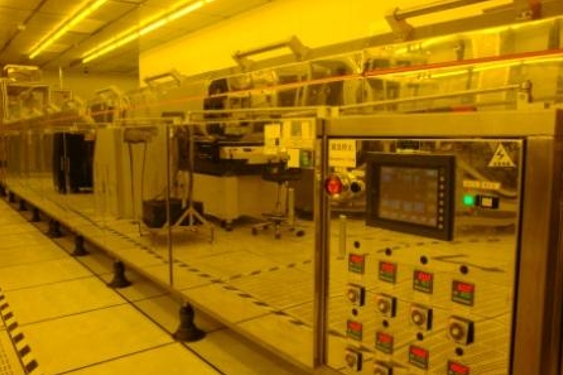

Photo lithography Process

Due to the needs of special applications, product development of photo lithography process is indispensable.

The minimum line width and line spacing of photo lithography process ITO pattern is 10-15μm.

The touch screen of photo lithography process can withstand ultra-low temperature -45°C and ultra-high temperature +85°C.

Copyright (c) 2020-2021 Fujian Wiwo Electronic Technology Co., Ltd. 备案号:闽ICP备18007537号