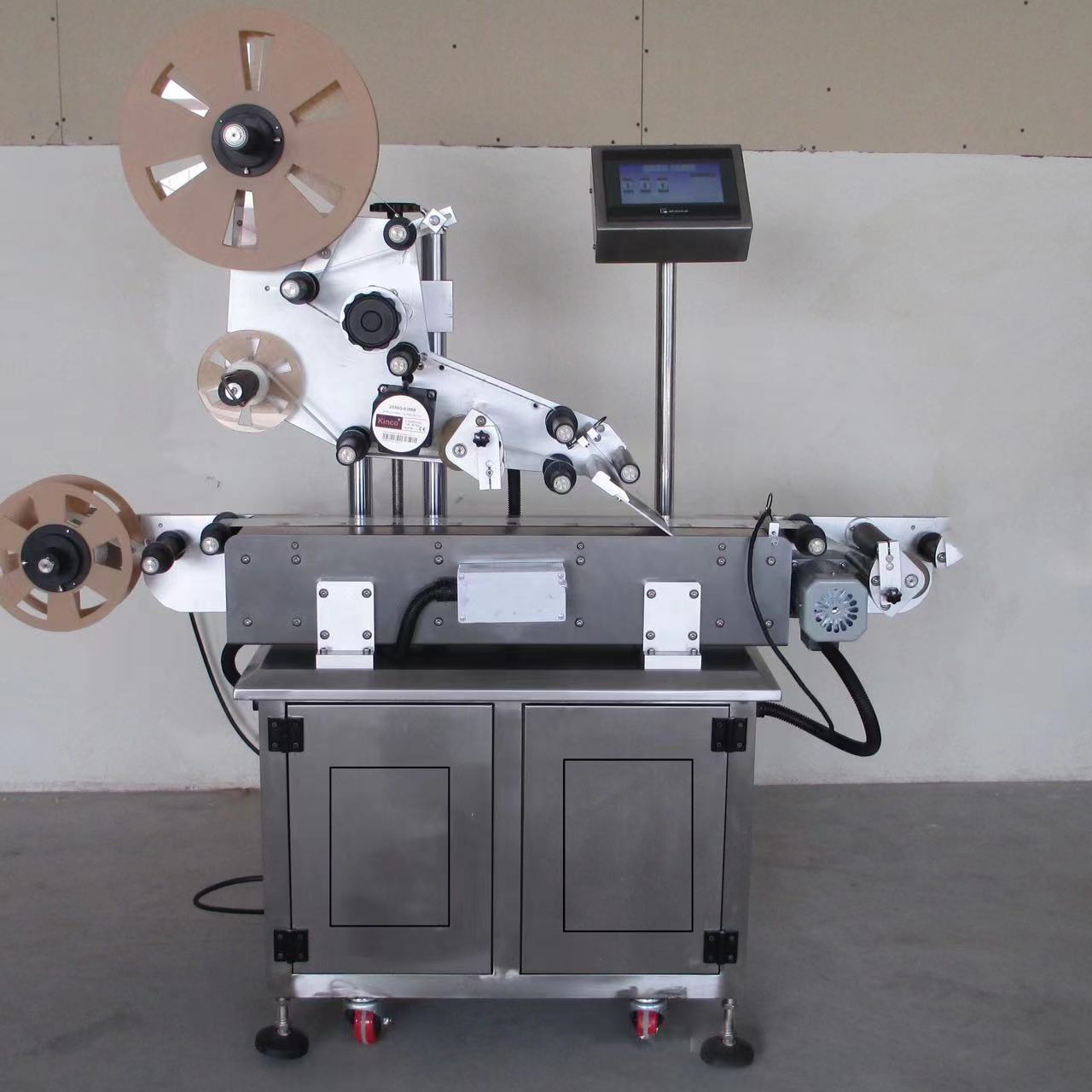

Labelling machine is a mechanical device that pastes and adheres labels in accordance with a preset position through an electromechanical control mechanism, which is widely used in the packaging process of various products. This kind of equipment can greatly reduce labour costs and improve production efficiency. Labelling machines can be divided into self-adhesive labelling machinery, paste labelling machinery, hot melt adhesive labelling machinery, sleeve labelling machinery and so on, according to the label adhesion method and the degree of automation. At the same time, according to the needs of the production line, the labelling machine is also divided into linear and rotary, as well as fully automatic and semi-automatic types.

The specific application of touch screen in the labelling machine is very extensive, it is used as the core interface of human-computer interaction, which greatly improves the operation convenience and intelligent level of the labelling machine.

The following are several major applications of touch screen in the labelling machine:

1. parameter setting and adjustment:

Users can intuitively set the production parameters of the labelling machine through the touch screen, such as label length, width, spacing, labelling speed, bottom speed, etc.. The setting of these parameters directly affects the accuracy and efficiency of labelling.

The touch screen also supports dynamic adjustment of parameters, users can adjust in real time according to the actual situation in the production process, in order to cope with the labelling needs of different products.

2. production monitoring and feedback:

The display can show the production status of the labelling machine in real time, including the current production quantity, labelling speed, fault information and so on. This enables the operator to grasp the production situation at any time, and find and solve problems in time.

When the labelling machine appears abnormal, the touch display will immediately show the alarm information, and may be accompanied by sound or light prompts to attract the attention of the operator.

3. data storage and traceability:

Some labelling machines have a data storage function, which can show key data in the production process through the touch display, such as the number of production, labelling success rate, the number of failures and so on. These data are important for production management and quality control.

Through the touch screen, users can easily query the historical data for production traceability and statistical analysis.

4. Remote control and monitoring:

In some advanced labelling machine systems, the touch screen also supports remote control and monitoring functions. Through the network connection, users can view the production status of the labelling machine in real time on the remote terminal, and carry out remote control and adjustment.

This not only improves the flexibility of production management, but also reduces the labour intensity of field operators.

5. Interface customisation and expansion:

The interface of the touch screen can be customized according to the actual needs of the user, including layout, colour, icons, etc.. This makes the interface more in line with the user's operating habits and workflow.

At the same time, the touch screen also supports extended functions, such as adding new control modules, sensor interfaces, etc., to meet the needs of different labelling applications.

Advantages of touch screen in labelling machine:

1. easy to operate: the touch screen interface is intuitive, the user can complete the complex production settings and monitoring through a simple touch operation, reducing the difficulty of operation.

2. real-time feedback: the touch screen can real-time display of production status and fault information to help users find and solve problems in a timely manner, improve production efficiency.

3. Intelligent control: touch screen and PLC control system combined to achieve the intelligent control of the labelling machine, according to the production demand for automatic adjustment of production parameters, improve production flexibility.

4. Reduce maintenance costs: touch screen reduces the use of traditional buttons and knobs, reducing the mechanical wear and tear and failure rate of the equipment, thereby reducing maintenance costs.

Touch screen application in the labelling machine challenges and solutions:

1. environmental adaptability: labelling machines may need to work in harsh production environments, such as high temperature, humidity, dust, etc. These environments may have an impact on the sensitivity and stability of the touch screen.

2. touch screen failure: touch screen as a precision electronic equipment, in the use of the process may fail, such as touch failure, display abnormalities.

3. Operating errors: Due to the easy operation of the touch screen, but there is also a risk of misuse, which may lead to incorrect setting of production parameters or equipment damage.

Solution:

1. Environmental adaptability enhancement: Select touch screen with high protection level, such as IP65 or above, to ensure that in the harsh environment can still work properly. At the same time, regular cleaning and maintenance of the touch screen to keep its surface clean and sensitive.

2. Failure prevention and troubleshooting: establish a perfect equipment maintenance system, regular inspection and maintenance of the touch screen. When the touch screen malfunction, follow the troubleshooting steps to check and repair to ensure the normal operation of the production line.

3. Operation training: Provide professional training for operators to make them master the operation methods and precautions of the touch screen and reduce the risk of misoperation. At the same time, set the operating privileges and password protection to prevent unauthorised personnel to operate the equipment.

In summary, the touch screen in the labelling machine plays a vital role, its application improves production efficiency, reduces maintenance costs, and achieve intelligent control. However, it also faces challenges such as environmental adaptability, faults and misoperation during use. These challenges can be effectively addressed through the selection of high protection grade touch screen, the establishment of a sound maintenance system and strengthen the operation of training measures to ensure the normal operation of the labelling machine and improve production efficiency.