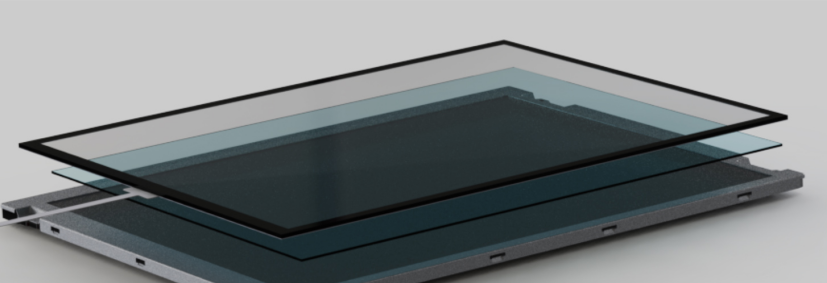

"Full bonding", also known as optical bonding, is a process in which a layer of resin (OCR) or film (OCA) is applied between the glass or touch screen of the display and the TFT LCD TFT panel to bond them together into a solid laminate without gaps or air pockets. When selecting a screen for any project, you should evaluate the environment and operating conditions that the screen will have to withstand. Industrial grade screen and panel PCS are rugged, with all types of functionality, and can withstand any type of application. One property that can be considered is optical bonding.

Optical bonding technology is popular in areas such as medical, military, transportation and retail, where higher performance displays are needed due to harsh environments. Optical bonding is suitable for industries that tend to use rugged displays in high-reliability environments or where displays need to be seen in high ambient light conditions. The optical bonding process is particularly suitable and efficient when applied to equipment operating outdoors or under high light conditions.

Optical Bonding Advantage

(1) Enhanced sunlight readability (about 5-10 times depending on the application)

(2) Increase impact resistance (~ 3-8 times, depending on the bonding cover glass).

(3) Strong impact resistance and vibration resistance.

(4) In the required application, the reflectivity of the touch screen is very low.

(5) Protect the display material from moisture, greatly improve the service life.

(6) High quality optical bonding of AR, AG, AR/AG/ hard coating/antifouling and other performance enhancing auxiliary components

Optical Bonding Technology Of WIWO

WIWO offers optical fit solutions for a wide variety of applications.

Hand-held devices such as outdoor use, navigation systems, industrial, medical displays and ATM devices for clear visibility in sunlight or bright environments.

Email: sales08@wiwotouch.com

Our team will reply you as soon as possible

call us with any questions

Have a nice day

Thankyou for your time