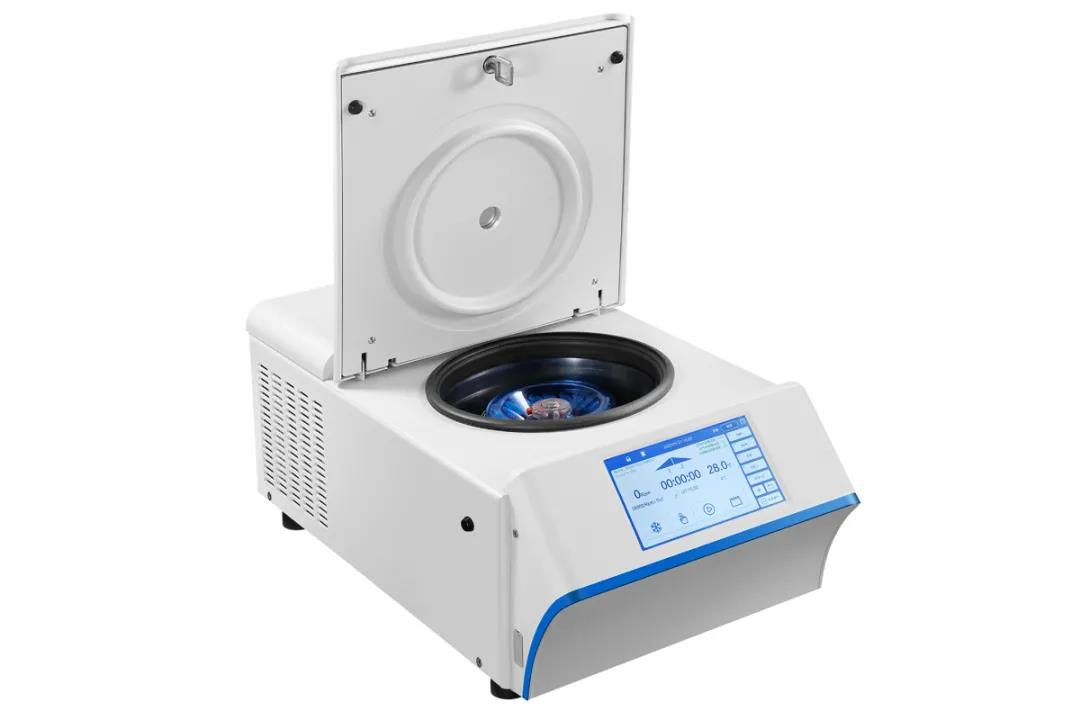

Centrifuge is an important equipment for separating cells, proteins or other substances in biological samples, and the touch screen can be used to control the rotational speed, time and temperature and other parameters of the centrifuge, so as to achieve more precise operation. With the continuous development of science and technology, touch screen technology is also more and more advanced and popular, the future application of touch screen on the centrifuge will become the development trend. At the same time, the touch screen can also provide more rich functions for the centrifuge, such as editable data analysis, to improve the intelligent level of the centrifuge.

The specific application of touch screen in the centrifuge:

Parameter setting and control: using the touch screen, users can set the centrifuge speed, time and temperature and other parameters through an intuitive interface. The operation interface of the touch screen can be designed in a simple and easy to understand, interactive and friendly form, enabling the user to quickly and accurately set and adjust parameters.

So what are the advantages of using a touch screen as an interactive interface on a centrifuge?

With the continuous expansion of the application field of centrifuges, users have higher and higher requirements for the convenience and ease of operation of centrifuges. The introduction of touch screen technology makes the operation of centrifuges more intuitive and simple, and reduces the learning cost and operating difficulty of users. Therefore, in today's highly competitive centrifuge market, centrifuges with touch screen technology will be more competitive.

With the continuous development of automation and intelligent technology, the control precision and automation degree of centrifuges requires more and more high. Touch screen technology can be combined with automation control systems to achieve remote monitoring and control of centrifuges and improve the degree of automation and operational stability of the equipment. This will help improve the performance and product quality of the centrifuge and meet the user's demand for high-precision separation and purification.

Touch screen technology can also introduce more intelligent functions for centrifuges. For example, through the touch screen, users can easily achieve centrifuge fault diagnosis, remote upgrade and maintenance operations. This will help improve the reliability and service life of the centrifuge and reduce users' maintenance costs.

Friendly interface: The interface design of the touch screen is simple and clear, and users can easily customise the main interface according to their own needs to improve the using experience.

Touch screen application in centrifuge needs to have the following characteristics:

Stability and reliability: centrifuge is a high-precision instrument, the touch screen needs to have good stability and reliability to ensure the accuracy of the operation and repeatability of the experiment.

Ease of operation: The touch screen on the centrifuge needs to be easy to operate, and the operation interface should be as simple as possible to understand and friendly to interact with, so that the user can get started quickly and without additional training costs.

High precision and sensitivity: the touch screen needs to have high precision and sensitivity, able to accurately capture the user's operating instructions, and respond quickly, without delay or mis-touch and other problems.

Waterproof and dustproof: As centrifuges may generate a large amount of sample liquid or gas during the experiment, the touch screen needs to be waterproof and dustproof to ensure long-term stable operation.

Durability: the touch screen needs to have good durability, can withstand long-term use and frequent operation of the test, not because of frequent use and damage or failure.