Glove-enabled touchscreen technology is an advanced interaction technology that allows users to operate touchscreen devices accurately and smoothly despite wearing gloves. This technology has a wide range of applications in a variety of fields such as industrial and medical.

Glove-enabled touch screen technology is mainly based on the improvement of capacitive touch screen. Traditional capacitive touch screens achieve touch operation by sensing the tiny capacitance changes formed between human fingers and the screen. However, gloves as insulators will isolate the body current, making it difficult for traditional capacitive screens to accurately recognise touch movements when wearing gloves. In order to solve this problem, glove-enabled touch screen technology uses a variety of methods:

1. Optimised sensor layout: By increasing the number of sensors and optimising the sensor layout, the touch screen's ability to capture weak signals is improved so that it can identify touch movements when wearing gloves.

2. Special algorithm support: Advanced algorithms are used to process and analyse touch signals to improve the accuracy and stability of touch recognition.

3. Conductive material integration: Some glove manufacturers integrate conductive materials into the glove fibres, making the gloves conductive while maintaining their original functionality, thus enabling better interaction with capacitive screens.

In the industrial sector, workers often need to wear gloves to maintain hygiene during production. When they need to control the machine equipment, always have to take off the gloves to touch the screen, which is a waste of time. Glove-enabled touchscreen technology allows workers to operate touchscreens directly on industrial equipment, improving ease of operation and accuracy. Glove-enabled touchscreens have a variety of important functions and roles, as well as some challenges. The following is a comprehensive analysis and specific explanation of these aspects.

The role of glove-enabled touchscreen technology:

1. Improve work efficiency: In the medical, food processing, chemical, cold storage warehouse and other industries, workers must wear gloves for safety or hygiene reasons. Glove-enabled touchscreens allow workers to operate equipment directly without removing their gloves, thus significantly improving work efficiency. For example, in medical scenarios, healthcare workers wearing sterilised gloves are able to directly operate touchscreen medical equipment, which not only improves work efficiency, but also reduces the risk of cross-infection.

2. Enhance the user experience: traditional capacitive screens are often difficult to accurately identify touch movements when wearing gloves, because gloves as an insulator will isolate the body current. By optimising the sensor layout and algorithms, the glove-enabled touch screen enhances the ability to capture weak signals, making it possible to accurately identify gloves even when they are separated from insulating materials, thus enhancing the user experience.

3. Expanding the scope of application: This technology not only supports ordinary gloves, but also recognises a wide range of gloves with different conductivity properties, such as gloves with micro-metallic fibres. This expands the range of applications for touchscreens in the industrial sector, enabling them to adapt to more diverse work environments.

4. Improve safety: outdoor operations in extreme climatic conditions, such as polar scientific research, logistics management in cold regions, etc., wearing gloves touch function ensures that the operator in the warmth at the same time can also be flexible to control the equipment, thus improving the safety of the operation.

Challenges of glove-enabled touch screen technology:

1. Technical challenges: the implementation of gloved touch control requires the optimisation of the sensor layout and algorithms of the touch panel to improve the ability to capture weak signals. This requires deep expertise and extensive practical experience on the part of the technology developer.

2. Cost issues: Glove-enabled touch panels typically require the use of higher quality components and more complex algorithms, which can result in higher costs than regular touch panels. How to ensure performance while reducing costs is a problem that manufacturers need to face.

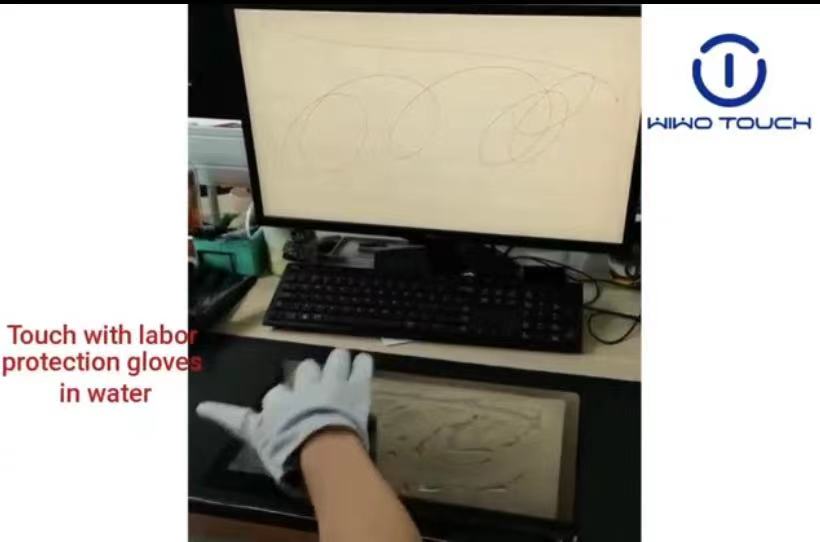

3. Environmental adaptability: Industrial environments are complex and changeable, and touch panels need to be waterproof, anti-disturbance and weather-resistant. How to maintain stable performance in these harsh environments is a problem that technology developers need to solve.

Solution:

1. Technological innovation: Through continuous technological innovation, optimise the sensor layout and algorithm of the touch panel to improve the touch screen's ability to capture weak signals. At the same time, develop capacitive screens with specific frequencies to better interact with gloves with different conductivity properties.

2. Specialised glove design: conductive gloves designed specifically for touch screens have appeared on the market, and these gloves are embedded with conductive materials that can effectively improve the interaction with capacitive screens. This solution does not directly improve the capacitive screen itself, but provides users with another option.

3. Customised solutions: for the needs of different industries, to provide customised touch screen solutions. For example, in the medical field, touchscreens specifically for medical equipment can be developed to meet the strict requirements of health and safety for healthcare professionals.

Specific example:

The touch screen with EETI chip can support gloved, wet and dry hand operation after professional debugging. It is equipped with a high-performance processor and supports a variety of operating systems such as (Linux, Andriod, Windows, etc.), providing powerful and smooth computing power. At the same time, the device also has the ability to support 6-12mm thick glass revision, able to withstand the impact of harsh environments and pollution. This kind of touch screen is widely used in industrial control panels, outdoor kiosks, medical equipment and other scenarios, effectively improving work efficiency and user experience.