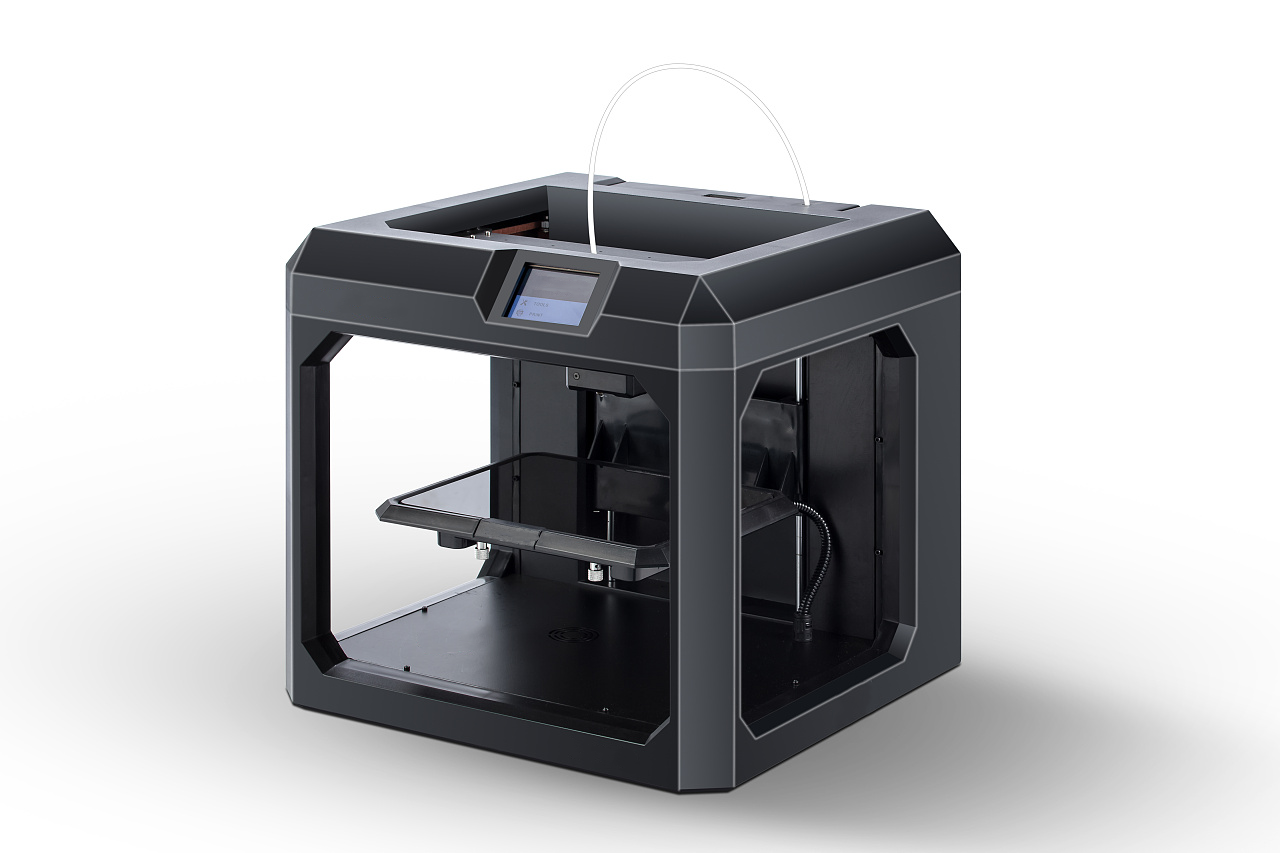

A 3D printer, also known as a three-dimensional printer (3D Printer, or 3DP for short), is an important device for rapid prototyping (Rapid Prototyping, RP) technology. It uses liquid photosensitive resin materials, molten plastic filaments, gypsum powder and other materials through layer-by-layer stacking, and produces a three-dimensional solid model in layers by spraying binder or extruding. The operation process is similar to that of traditional printers, but the difference is that traditional printers print two-dimensional flat drawings, while 3D printers print three-dimensional entities.

Since its origin in the United States in the 1980s, 3D printing technology has rapidly developed in Japan and Europe, becoming a major breakthrough in the field of manufacturing technology in recent years. It integrates CAD, numerical control technology, laser technology and materials science and engineering and other advanced technologies, can automatically and quickly design ideas into a certain structure and function of the prototype or direct manufacturing parts, greatly shortening the product development cycle, improve production efficiency and reduce production costs.

Capacitive touch screen technology is a touch control technology based on human current sensing. In the 3D printer application environment, the touch screen replaces the traditional physical buttons as the interaction interface, bringing multiple advantages:

1. Convenient operation: Users only need to click and drag on the screen through the finger or stylus to achieve the control of 3D printers, without the use of physical buttons or knobs, the operation is more intuitive and convenient.

2. Rich display information: the monitor can display text, images, video and other information at the same time, the user can intuitively through the touch screen to understand the 3D printer's working status, parameter settings, troubleshooting and other information, to improve the degree of visualisation and information technology of the equipment.

3. Improved safety: touch screen control can avoid misoperation or failure due to mechanical wear and tear of physical buttons, poor contact and other issues, improving the safety and reliability of the equipment.

4. Strong expandability: the software and hardware of the touch screen control system are modular, which can be customised and expanded according to the actual needs, and is convenient for users to carry out secondary development and upgrading.

5. Convenient maintenance: through the touch screen, users can monitor the 3D printer's operating status and fault information in real time, which is convenient for maintenance personnel to carry out troubleshooting and repair. At the same time, the touch screen operation records and logs are also convenient for maintenance personnel to track and manage the use of equipment.

Although the touch screen in 3D printers and other industrial equipment to show many advantages, but also faces some challenges:

1. Environmental adaptability:

Oil and dust: The working environment of 3D printers may be relatively complex, and oil and dust can easily adhere to the surface of the touch screen, affecting the touch sensitivity and display effect.

Temperature changes: Temperature changes in the working environment may affect the response speed and accuracy of the touch screen.

2. Durability:

Frequent touch: In long time use, the touch screen needs to withstand frequent touch operations, which may lead to surface wear or internal component damage.

Mechanical shock: If the 3D printer is subjected to accidental impact or vibration, the touch screen may be damaged by mechanical shock.

3. Human-computer interaction complexity:

Functional complexity: With the increasing functions of 3D printers, the touch screen needs to integrate more operating options and settings, which increases the learning cost of users.

Operation accuracy: For 3D printing tasks that require high-precision operation, the response accuracy and stability of the touch screen may face challenges.

4. Maintenance and repair:

High maintenance cost: Once the touch screen is damaged, the entire assembly may need to be replaced, resulting in high maintenance costs.

Difficult to repair: the internal structure of the touch screen is complex, and repair requires specialised techniques and equipment.

Solution:

1. Improve environmental adaptability:

Adopt anti-fouling and anti-dust design: Adopt anti-fouling and anti-dust materials on the surface of the touch screen to reduce the adhesion of oil and dust.

Increase the temperature adaptability: choose a wide temperature operating touch screen components to ensure that in different temperature environments can work normally.

2. Enhance durability:

Selection of high-quality materials: the surface of the touch screen is made of wear-resistant and scratch-resistant materials to improve wear resistance.

Enhanced structural design: Optimise the structural design of the touch screen to improve its impact resistance.

3. Optimise human-computer interaction:

Simplify the operation interface: according to the user's habits and needs, reasonably design the operation interface of the touch screen and reduce unnecessary operation options and setting items.

Provide operation guide: provide users with detailed operation guide and tutorials to help users quickly master the use of the touch screen.

4. Reduce maintenance and repair costs:

Provide easy maintenance design: Consider easy maintenance in the design of the touch screen, so that it is easy for users or maintenance personnel to quickly replace damaged parts.

Strengthen after-sales service: establish a perfect after-sales service system to provide users with timely and professional technical support and maintenance services.

In summary, the touch screen in the 3D printer application environment shows significant advantages, but also faces some challenges. Through reasonable maintenance and repair, as well as timely troubleshooting and solutions, the advantages of touch screen can be maximised to improve the efficiency and safety of 3D printers.